What’s the Difference Between Cad and Cam?

CAD or Computer-aided design is the use of software to create two- or three-dimensional designs, while CAM, computer-aided manufacturing, is the use of computer software and machinery to manufacture three-dimensional objects. For CAD users the end product is a design or image. For CAM users the end product is an object.

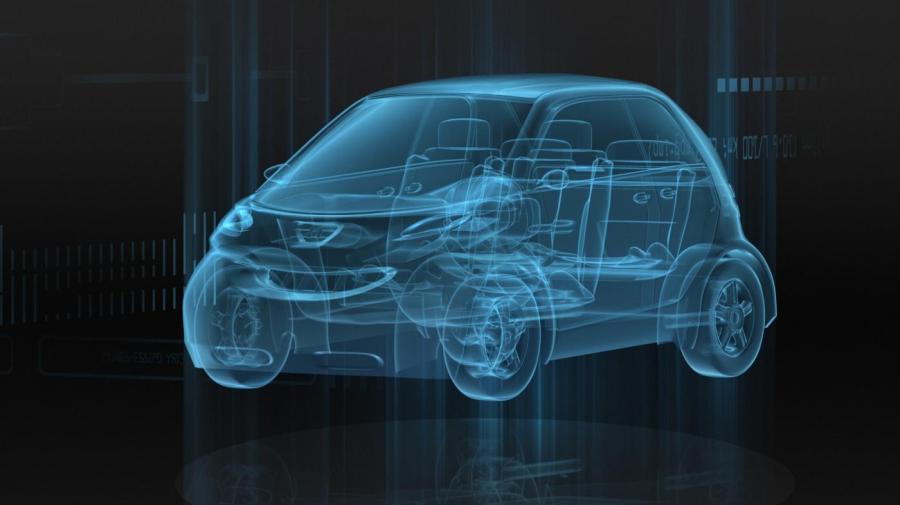

CAD is often used by product or industrial designers to create renderings and two-dimensional vector-based drawings of models. CAD drawings demonstrate the size, appearance, texture and material of products that have yet to be manufactured. CAD drawings are used to demonstrate how an object is constructed and the placement of its component parts. According to computer software companies such as Siemens, CAD software offers better visualization of the design, improves accuracy and eliminates error during the manufacturing process.

Computer-aided manufacturing, on the other hand, uses computers to build or manufacture objects. Machinery programmable by computer software facilitates and automates the manufacturing process, making the process faster and more efficient. Since CAM optimizes the production process, it reduces waste of raw materials and manufacturing errors. Often, CAM is integrated with CAD programs during manufacturing. In other words, CAD and CAM work in tandem. A design or object is created using CAD software. Then, the design is transmitted to CAM, which builds the design.